EPDM Rubber Products Manufacturer | Custom Extrusions, Sheets & Molded Seals

The "Outdoor King": High-Performance Ethylene Propylene Diene Monomer Solutions Direct from the Factory

Source Direct from RiseUp Rubber

Tired of paying distributor markups for standard sheets? RiseUp Rubber is a premier manufacturer of EPDM products. From custom compounding to precision extrusion and molding, we provide the industrial-grade durability your project demands—shipped globally from our ISO-certified facility.

What is EPDM Rubber? What is EPDM exactly?

The definition of EPDM stands for Ethylene Propylene Diene Monomer (M-Class rubber).

• The Chemistry: Unlike Natural Rubber which has a double-bond backbone susceptible to cracking, EPDM features a saturated polymer backbone.

• The Result: This unique epdm rubber structure gives it virtual immunity to sunlight (UV), ozone, and extreme weather. It is the gold standard for outdoor sealing applications where other rubbers fail.

• The Meaning: When engineers ask for the meaning of EPDM, they are essentially asking for “Weather Resistance.”

Why EPDM is the "Outdoor King": Material Properties

Unmatched Weather Resistance The primary reason engineers select Ethylene Propylene Rubber is its saturated polymer backbone. Unlike other elastomers that degrade, EPDM rubber characteristics include:

• UV & Ozone Immunity: It will not crack or craze even after years of direct sunlight exposure.

• Water & Steam Resistance:

EPDM outperforms FKM and Silicone in hot water and steam applications, making it ideal for radiator hoses and heating systems.

Technical Performance Data Understanding the epdm material properties helps in selecting the right grade.

| Feature | Performance Specs |

| Working Temp Range | -50°C to +150°C (-58°F to +302°F) |

| Peak Temp (Intermittent) | Up to +170°C (Peroxide Cured) |

| Chemical Resistance | Excellent for Ketones, Dilute Acids, Alkalies, and Brake Fluids (DOT 3/4). |

| Weakness | NOT Oil Resistant. (Swells in Gasoline/Diesel). |

Custom EPDM Manufacturing: From Profiles to Precision Parts

At RiseUp Rubber, we don’t just stock sheets; we engineer solutions. Our facility handles three primary manufacturing processes to create diverse EPDM products:

1. Custom EPDM Extrusions (Sealing Profiles) We extrude continuous profiles for weatherstripping and glazing.

• Capabilities: D-strips, U-channels, P-profiles, and complex glazing seals.

• Material: Available in both solid (dense) and closed-cell sponge EPDM seal material.

• Application: Perfect for automotive door seals and architectural window gaskets.

2. Precision Molded Components Need a 3D shape? Our compression and injection molding services deliver tight tolerances.

• Products: Custom grommets, boots, bellows, and die-cut EPDM gasket solutions.

• Advantage: We design and cut our own molds (in-house tooling), ensuring your specific epdm gasket material fits perfectly with faster lead times.

3. EPDM Rubber Hoses & Tubing As a specialized EPDM manufacture expert, we produce reinforced tubing for fluid transfer.

• Types: Heater hoses, radiator hoses, and steam lines.

• Performance: Our EPDM rubber hose meets SAE J20 standards, resisting electrochemical degradation and high engine temperatures.

Industry Applications: Where EPDM Excels

Because of its stability, EPDM uses span across industries that require long-term reliability in harsh environments. As a global EPDM supplier, we serve three key sectors:

1. Automotive Applications (The Standard

EPDM is the dominant material for modern vehicles due to its heat and weather resistance.

• Under the Hood: Coolant hoses and radiator tubes that resist ethylene glycol and high heat. It is also compatible with DOT 3 and DOT 4 brake fluids.

• Body Sealing: Door seals, trunk seals, and window channels that must endure years of sun and rain without shrinking.

2. Construction & Green Energy (The “New” Standard)

Solar PV Sealing: We supply UV-stable EPDM seals for solar panels and photovoltaic clamps, ensuring 20+ years of service life on rooftops.

• Roofing & Glazing: EPDM membranes and window gaskets used in skyscrapers to prevent water ingress

3. Water & Industrial Systems

Steam Handling: Unlike many rubbers that fail in steam, EPDM handles moist heat up to +150°C, making it ideal for industrial steam gaskets.

• Water Treatment: O-rings for water filtration systems (Chloramine resistance).

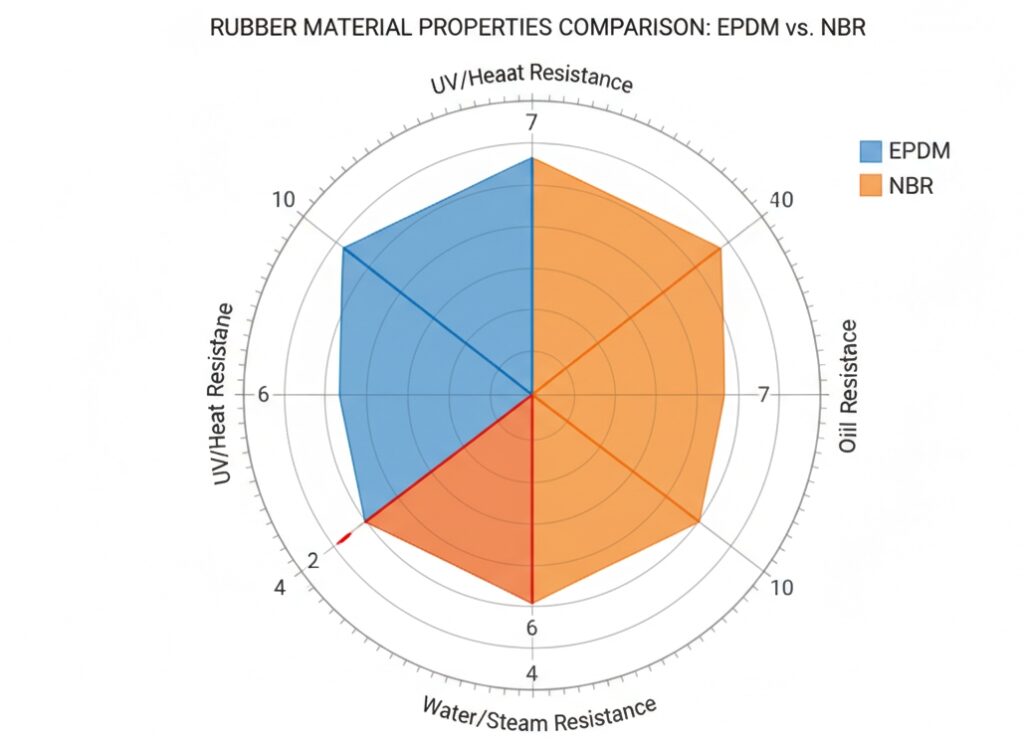

Material Warning: Do NOT use EPDM for gasoline, diesel, or mineral oil applications. For fuel lines, please request [Nitrile (NBR)] or [FKM]

Technical Data & Frequently Asked Questions

Standard EPDM Specifications We customize compounds to your needs, but here are the typical properties for our industrial-grade material.

| Property | Value / Range |

| Polymer Name | Ethylene Propylene Diene Monomer |

| Common Density | 1.15 – 1.25 g/cm³ (See note on epdm density) |

| Hardness (Durometer) | 30 – 90 Shore A (Standard is 60/70) |

| Tensile Strength | 5 – 15 MPa (High strength available) |

| Elongation at Break | 300% – 600% |

| Color | Black (Standard), White, Grey, or Custom |

Tech Note on Density: Sponge EPDM density is much lower (approx 0.4 - 0.8 g/cm³).

FAQ: Expert Answers

Q: What is the correct spelling? Is it EBDM or EPDM?

A: The correct term is EPDM. However, it is frequently misspelled as ebdm rubber, epmd rubber, or even epdem. Regardless of how you type it, if you are looking for weather-resistant rubber, you are in the right place.

Q: What is EPDM material’s biggest weakness?

A: Oil resistance. What is EPDM materialNOT good for? Contact with gasoline, diesel, or mineral oils, which will cause it to swell and fail. For oily environments, choose Nitrile (NBR).

Q: What does the “E.P.D.M” meaning stand for in chemistry?

A: The e.p.d.m meaningbreaks down to the monomers used: Ethylene, Propylene, Diene, and Monomer (M-class). This chemical structure is what provides its exceptional heat and ozone resistance.

Q: Are you a stockist or a manufacturer?

A: We are a direct supplier of EPDM and a manufacturer. We produce the raw compound and finish the goods (molding/extrusion) in-house, offering better prices than mere stockists.

MOQ 500 pcs, Accept Customization for Small Order. Design Products as Your Idea.

Direct from the Source: Partner with RiseUp Rubber

Why settle for standard catalog parts when you can get custom solutions for less? As a dedicated manufacturer of EPDM, RiseUp Rubber eliminates the middleman, offering you:

• Factory-Direct Pricing: No distributor markups.

• Custom Compounding: We adjust the formula to meet your specific hardness, color, and UV resistance needs.

• One-Stop Service: From raw material mixing to final extrusion or molding.

Ready to weather the elements? Contact our engineering team today for a fast, competitive quote on your EPDM rubber project.

Package Method

Request A Free Quote

"Take The Efficient 2025 Booster For Your Business Now "

Alan Chen

Product Sales Manager & Rubber Specialist at RISEUP