Precision Liquid Silicone Rubber (LSR) Injection Molding Services Subtitle: From Prototype to Mass Production: The Trusted LSR Manufacturer for Medical, Automotive, and Consumer Electronics.

Engineering the Future with Liquid Silicone RiseUp Rubber delivers high-performance silicone rubber products that demand extreme heat resistance, biocompatibility, and intricate geometries.

• Medical Grade Purity: ISO 13485 certified production in Class 100K cleanrooms.

• Flash-Less Technology: Advanced cold-runner systems reduce waste and eliminate trimming.

• Rapid Scalability: Our liquid silicone rubber injection molding process ensures consistent quality from prototype to mass production.

Why Leading Brands Choose Us as Their Silicone Rubber Manufacturer

1. Speed & Efficiency Our flash-less tooling technology reduces cycle times by up to 30% compared to traditional silicone rubber manufacturers.

2. Micrometer Precision We don’t just mold; we measure. As a premier silicone parts manufacturer, we utilize Automated Optical Inspection (AOI) to ensure tolerances of ±0.01mm.

3. Material Purity & Partnership We maintain direct partnerships with top silicone rubber suppliers (Dow, Wacker, Momentive) to guarantee 100% genuine LSR material.

4. End-to-End Fabrication Beyond molding, our silicone rubber fabrication services include post-curing, printing, and cleanroom packaging.

What is Liquid Silicone Rubber (LSR)? Performance Beyond Limits

Defining the Material What is liquid silicone rubber? Unlike solid rubber, LSR material is a two-component platinum-cured elastomer that starts as a liquid, enabling closed-loop automation.

Technical Comparison: LSR vs. Solid Silicone (HCR) Engineers often ask: “Why switch to LSR liquid silicone rubber?”

| Feature | Liquid Silicone Rubber (LSR) | Solid Silicone (HCR) |

| State | Pumpable Liquid (Low Viscosity) | Solid Brick (High Viscosity) |

| Process | Automated Injection Molding | Compression / Transfer |

| Cycle Time | Fast (Seconds) | Slow (Minutes) |

| Waste | Low (Cold Runner) | High (Flash & Sprues) |

| Precision | Micron Level (±0.01mm) | Standard (±0.1mm) |

Advanced Liquid Silicone Rubber Molding Capabilities

1. Custom LSR Injection Molding We utilize advanced liquid silicone rubber injection molding machines with cold runner systems for zero sprue waste.

2. 2-Shot (2K) & Overmolding We bond LSR material directly to thermoplastics or metal inserts. Chemical bonding eliminates primers.

3. Micro-Molding For parts <1g, our precision silicone rubber fabrication process delivers microscopic accuracy for medical valves.

Diverse Applications of LSR Silicone Products

1. Medical & Healthcare Class VI medical-grade components produced in ISO 13485 cleanrooms.

• Parts: Masks, duckbill valves, catheter components.

2. Automotive & Industrial Silicone rubber products for extreme environments (-60°C to +250°C).

• Parts: Connector seals, O-rings, spark plug boots.

3. Consumer Electronics High clarity and soft-touch aesthetics.

• Parts: Earbud tips, smart watch bands, baby products.

MOQ 500 pcs, Accept Customization for Small Order. Design Products as Your Idea.

Frequently Asked Questions about LSR Manufacturing

Q: What is the difference between “LSR Liquid Silicone Rubber” and standard silicone?

A: LSR liquid silicone rubber is a liquid raw material pumped for automated curing, while standard silicone is a solid gum requiring manual labor.

Q: I see the term “Liquid Silicon Rubber” often. Is that different?

A: No. Many search for liquid silicon rubber, but it is the same as Silicone. RiseUp provides the highest grade material regardless of spelling.

Q: How do I choose the right supplier silicone rubber grade?

A: As an experienced supplier silicone rubber partner, we recommend grades based on clarity, biocompatibility, or resistance.

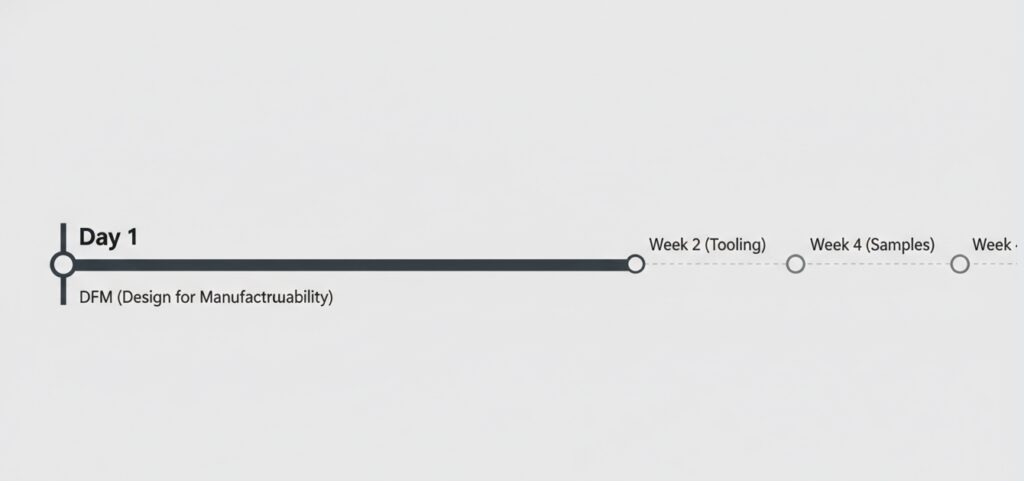

Q: What is your lead time? A: Because we are an LSR molding company with in-house tooling:

• Prototypes: 7-10 Days.

• Production: 15-25 Days.

Budget Constraints or Lower Volume? LSR tooling is an investment designed for high performance. If you are developing a low-volume prototype (under 1,000 units) or using standard solid silicone (HCR), our [Compression Molding] or [Rubber Transfer Molding] services offer significantly lower tooling entry costs for industrial grade parts

Partner with a Top-Tier LSR Manufacturer Today

Don’t let delays hold you back. RiseUp Rubber combines the speed of liquid silicone rubber injection molding with ISO 13485 quality.

Get Your DFM Report & Quote within 24 Hours

Package Method

Request A Free Quote

"Take The Efficient 2025 Booster For Your Business Now "

Alan Chen

Product Sales Manager & Rubber Specialist at RISEUP