Industrial Natural Rubber Products & Custom Sealing Solutions

Premier Manufacturer of Natural Rubber Gaskets, O-Rings, and Tubing | Factory Direct

Welcome to RISEUP Rubber, your trusted partner for high-performance industrial components. We specialize in transforming pure, high-grade natural rubber (NR) into precision natural rubber products designed for critical sealing and fluid transfer applications.

Leveraging unique natural rubber properties—including exceptional elasticity, high tensile strength, and superior abrasion resistance—we deliver custom solutions that outperform synthetic alternatives in dynamic applications. Whether you need die-cut gaskets, molded seals, or flexible tubing, our manufacturing capabilities ensure tight tolerances and consistent quality.

Product Categories

Molded Natural Rubber Seals & O-Rings

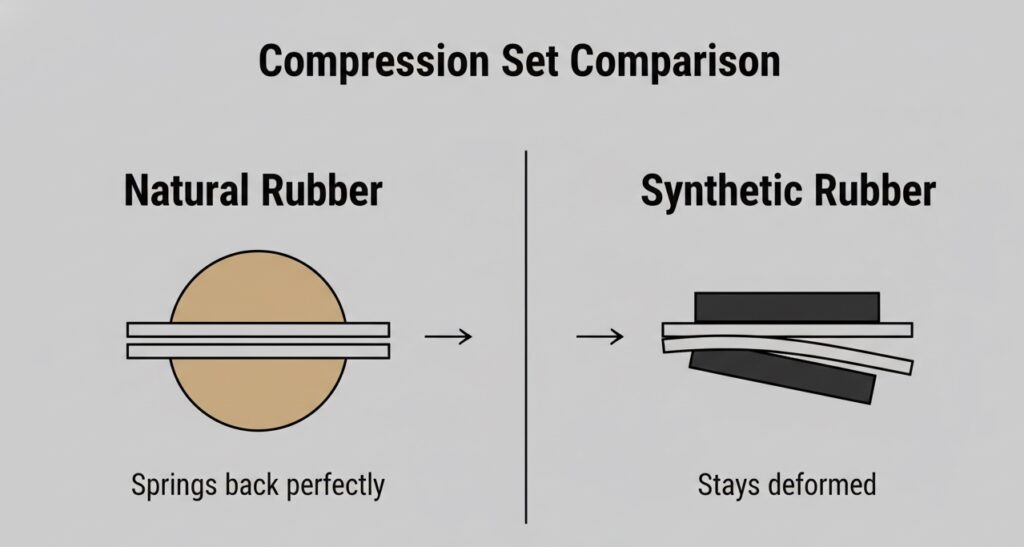

ngineered for superior resilience. Our molded natural rubber seals offer excellent recovery properties (low compression set) and high tensile strength. Ideal for dynamic sealing applications where synthetic rubber fails to rebound. more details [view o-rings & seals ]

Precision Die-Cut Natural Rubber Gaskets

ustom-fabricated flat gaskets cut to your exact CAD specifications. We utilize high-grade natural rubber sheeting to produce durable flange gaskets and washers perfect for vibration isolation and low-pressure water systems. more details[ view gaskets ]

Flexible Natural Rubber Tubing (Latex)

remium amber gum rubber tubing featuring smooth inner bores for unrestricted flow. Known for its extreme flexibility and tear resistance, making it the industry standard for laboratory, medical, and industrial fluid transfer. more details [view tubing ]

Why Choose Natural Rubber (NR) for Sealing?

Superior Mechanical Properties Natural Rubber (Isoprene) remains the gold standard for applications requiring dynamic flexibility. Unlike many synthetic compounds, pure natural rubber offers:

• High Tensile Strength: Exceptional resistance to tearing and cutting, making it ideal for abrasive environments like slurry transfer or mining chutes.

• Unmatched Elasticity: Delivers superior “snap-back” performance. In sealing applications, this translates to a low compression set—meaning your natural rubber o-rings won’t flatten out over time, ensuring a leak-proof seal for years.

• Cold Weather Flexibility: Retains flexibility down to -50°C (-58°F), whereas PVC or other synthetics may become brittle and crack.

Material Limitations Note: Natural Rubber is NOT recommended for applications involving exposure to petroleum oils, fuels, or non-polar solvents, as it will swell and degrade. For oil-resistant applications, please ask about our Nitrile (NBR) solutions.

General Technical Specifications

| Property | Typical Value / Range |

| Material Code | NR / Polyisoprene |

| Durometer (Hardness) | 40 – 70 Shore A (Customizable) |

| Tensile Strength | 2500 – 3500 PSI |

| Elongation at Break | 500% – 700% |

| Temperature Range | -50°C to +80°C (-58°F to +176°F) |

| Abrasion Resistance | Excellent |

| Oil Resistance | Poor |

Advanced Rubber Product Manufacturing Services

We don’t just supply standard parts; we engineer solutions. As a full-service manufacturer, we offer end-to-end rubber product manufacturing capabilities from prototype to mass production.

1. Precision Compression Molding: Ideal for Natural Rubber O-rings, hatch seals, and complex 3D shapes. Our tooling ensures flash-free parts with tight dimensional tolerances.

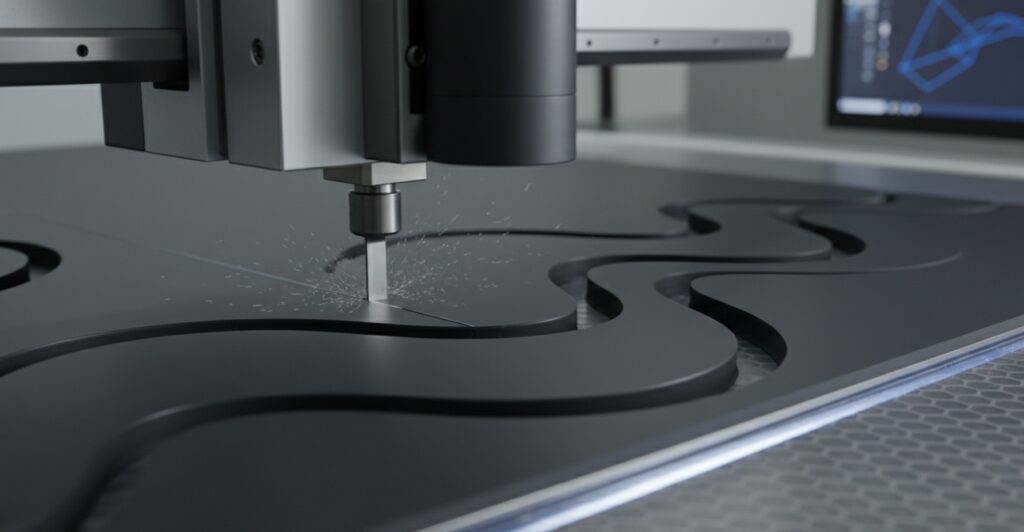

2. Die-Cutting & CNC Fabrication: We convert natural rubber sheets into custom gaskets using high-speed die-cutting (for volume) or digital CNC cutting (for prototypes/no tooling costs). We can cut to any ASME/ANSI flange standard or your custom CAD drawing.

3. Continuous Extrusion: We run dedicated lines for natural rubber tubing and custom profiles. Our curing process ensures consistent wall thickness and smooth surface finish.

Quality Assurance: All production batches are traceable. We perform in-house testing for hardness (Shore A), specific gravity, and tensile strength.

Frequently Asked Questions (FAQ)

Q: What are the main uses of natural rubber in industrial applications?

A: Due to its excellent elasticity and tear resistance, natural rubber is primarily used in water sealing systems, slurry transfer hoses, and vibration dampening mounts.

Q: Can you manufacture custom sizes based on my drawings?

A: Yes. We accept CAD files (DWG, DXF, STP) or physical samples. We can customize wall thickness or unique cross-sections.

Q: Do you offer samples for testing?

A: Absolutely. For standard items, we offer free samples. For custom molded parts, we provide prototype samples (5-7 days) before mass production.

Q: What is your typical lead time?

A: Standard stock items ship within 2-3 days. Custom production runs typically require 2-3 weeks.

Ready to Start Your Project? Sub-text: Get a competitive quote for high-quality natural rubber sealing solutions. Upload your drawing or specifications today.

MOQ 500 pcs, Accept Customization for Small Order. Design Products as Your Idea.

Package Method

Request A Free Quote

"Take The Efficient 2025 Booster For Your Business Now "

Alan Chen

Product Sales Manager & Rubber Specialist at RISEUP