Precision Rubber Transfer Molding Services | Complex Bonding & Tight Tolerances

The "Golden Mean" of Molding: Superior Insert Bonding and Dimensional Control without High Injection Tooling Costs.

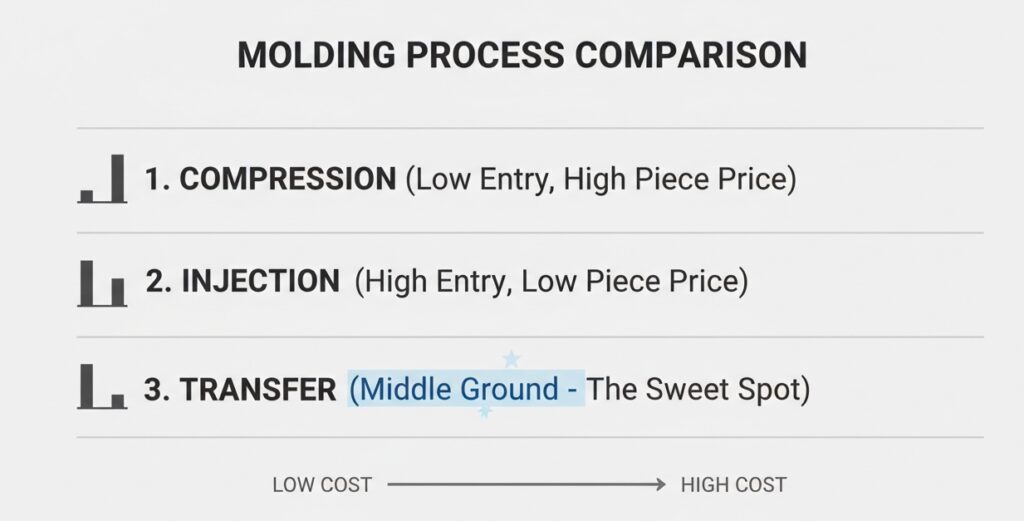

Why Choose Transfer Molding? Bridging the gap between Compression and Injection, our Rubber Transfer Molding process is the engineer’s choice for intricate geometries.

Ideal for Inserts: The low-pressure cavity fill allows for delicate metal-to-rubber bonding without shifting or damaging the insert.

Reduced Finishing: Unlike compression molding, our transfer process minimizes flash, delivering near-net-shape parts right out of the mold.

Material Versatility: From FKM and Silicone to NBR and EPDM, we mold it all.

The Transfer Molding Process: Efficiency Meets Precision

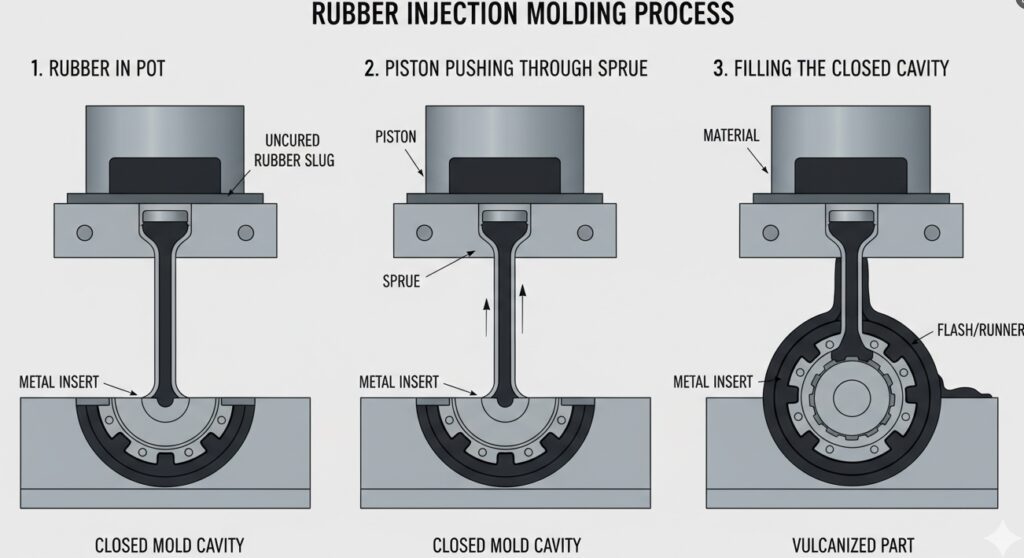

What is Transfer Molding? Unlike standard compression molding where material is placed directly into an open cavity, the rubber transfer molding process utilizes a “Pot” and “Piston” system.

1.Pre-Heating: Uncured rubber is placed in a chamber (the pot) above the mold cavity.

2. Injection: A piston forces the rubber through narrow channels (sprues) into a closed mold cavity.

3. Curing: Because the rubber is pre-heated by friction as it enters, the cure time is significantly faster than compression molding.

Why the “Closed Mold” Matters This mechanism is the key to quality. By injecting into a mold that is already closed, transfer moulding eliminates the parting-line variation often seen in compression parts. This ensures consistent vertical dimensions, making it the superior rubber molding process for parts requiring tight tolerances.

Process Comparison: Transfer vs. Compression vs. Injection

Making the Right Choice Choosing the right rubber molding process depends on your volume, budget, and precision requirements. While rubber compression molding is cheap and rubber injection molding is fast, Transfer Molding occupies the strategic middle ground.

| Feature | Compression Molding | Transfer Molding (RiseUp) | Injection Molding |

| Tooling Cost | Low ($) | Moderate ($$) | High ($$$$) |

| Precision | Low/Medium | High (Closed Mold) | High |

| Cycle Time | Slow | Medium/Fast | Very Fast |

| Insert Bonding | Difficult | Excellent | Good |

| Best For | Simple, Big Parts | Complex, Bonded Parts | High Volume (100k+) |

Need Medical-Grade Purity or High-Volume Automation? While Transfer Molding is excellent for industrial bonded parts, it uses solid rubber stocks. For applications requiring Class VI biocompatibility or optical clarity (like lenses), we recommend our [Liquid Silicone Rubber (LSR) Molding] services, which offer a completely touch-free, automated production environment.

Expert Rubber-to-Metal Bonding Capabilities

Why Transfer Molding is Best for Inserts For engineers designing custom molded partsthat require metal skeletons, sensors, or brass fittings, Transfer Molding is superior to Compression Molding.

Gentle Flow: In the rubber molding process, the material enters the cavity as a liquid. This low-viscosity flow surrounds the metal insert gently, preventing the “insert shift” or damage often caused by the high pressure of compression molding.

Encapsulation: It is ideal for over-molding delicate electronics or complex metal geometries where complete encapsulation is required.

Bonding Material Compatibility Chart We ensure chemical-grade adhesion for various substrates:

| Substrate (Insert) | Compatible Rubber Compounds |

| Steel / Stainless Steel | NBR, EPDM, FKM (Viton®) |

| Brass / Copper | NBR, VMQ (Silicone) |

| Aluminum | Silicone, EPDM |

| Plastics (Nylon/PEEK) | Silicone (Low Temp Cure) |

Our transfer molding process is compatible with a wide range of elastomers. We frequently mold [EPDM] for outdoor seals, [Nitrile (NBR)] for oil-resistant gaskets, [FKM]or[FVMQ ]for heat-resistant seals,[NR] for low temperature resistance gaskets

Frequently Asked Questions about Transfer Molding

Q: What is the difference between “Transfer Molding” and “Transfer Moulding”?

A: There is no technical difference. Transfer molding is the standard US spelling, while transfer moulding is commonly used in the UK, Australia, and Europe. At RiseUp Rubber, we serve global markets and adhere to international ISO standards regardless of the spelling.

Q: Is Transfer Molding cheaper than Rubber Injection Molding?

A: In terms of tooling, yes. Rubber injection molding molds are complex and expensive (often $10k+). Transfer molds are simpler and typically cost 30% to 50% less. For production volumes between 1,000 and 50,000 pieces, Transfer is the most cost-effective solution.

Q: Can you do “Transfermolding” for Silicone?

A: Yes. While people often search for transfermolding (one word), the process is excellent for gum-based Silicone (VMQ) and Fluorosilicone (FVMQ). It is particularly useful for silicone keypads or gaskets requiring metal contacts.

Q: Does the process create waste?

A: Unlike injection molding, Transfer Molding does leave a “cull pad” (excess rubber in the pot). However, for high-value materials or complex custom molded parts, the cost of this small waste is outweighed by the savings in labor and the reduction of rejected parts due to flash.

Start Your Transfer Molding Project with RiseUp

Precision, Efficiency, and Value

You don’t have to compromise between quality and cost. With RiseUp Rubber’s Rubber Transfer Molding services, you get the tight tolerances of injection molding with significantly lower tooling investment.

Whether you need complex rubber-to-metal bonding or intricate custom molded parts, our engineering team is ready to guide you from prototype to production.

Ready to upgrade your molding process?

MOQ 500 pcs, Accept Customization for Small Order. Design Products as Your Idea.

Package Method

Request A Free Quote

"Take The Efficient 2025 Booster For Your Business Now "

Alan Chen

Product Sales Manager & Rubber Specialist at RISEUP